Swedish nuclear energy vegetation are implementing 3D printing to deal with spare components challenges as reactors prolong their working lives to 80 years. Based on Björn Forssgren, metallic supplies specialist at Ringhals nuclear energy plant, the flexibility to regulate manufacturing internally might “contribute to elevated availability for our manufacturing items, which means extra fossil-free electrical energy manufacturing.”

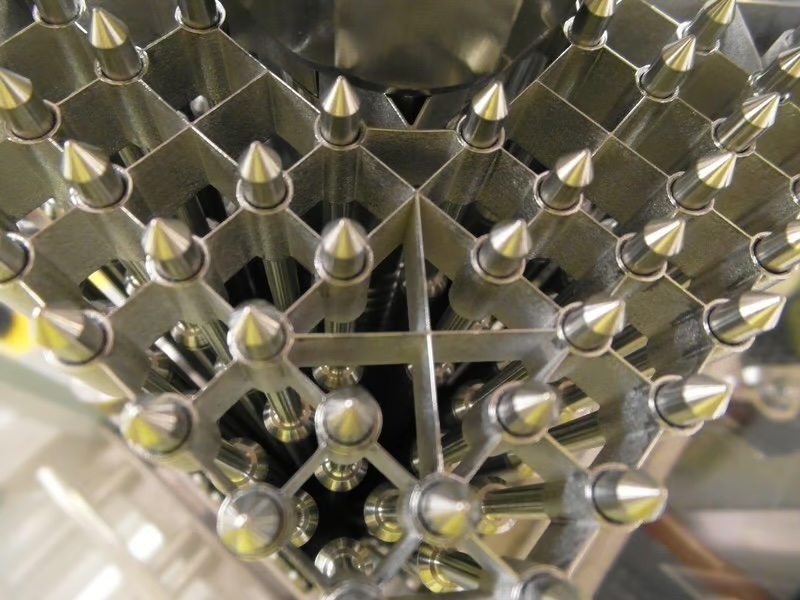

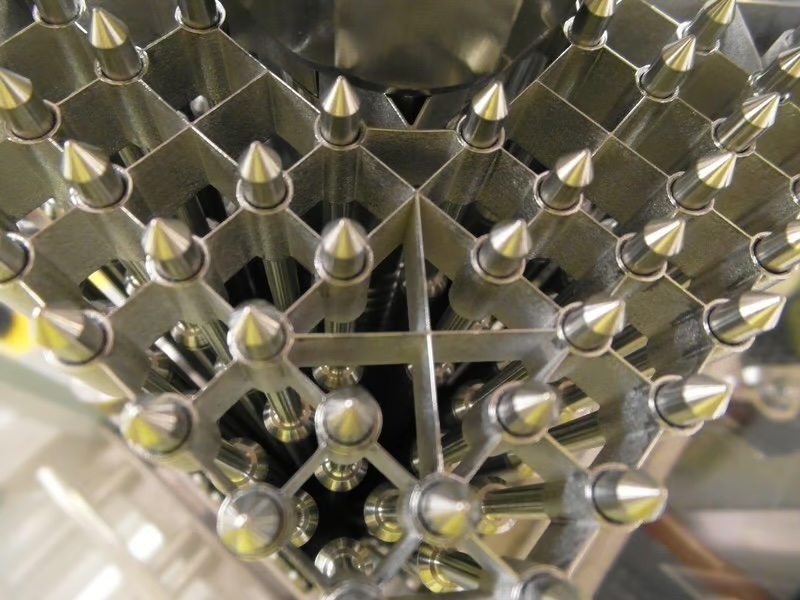

In 2017, Ringhals joined a collaborative 3D printing initiative with different firms, now managed by Analysis Institutes of Sweden (RISE). The partnership, which has expanded to 21 firms, focuses on creating AM capabilities for numerous parts together with pipes, valves, and pump housings. Testing exhibits that 3D-printed components preserve equal or superior structural integrity in comparison with historically manufactured parts.

AM-manufactured components are already put in in all three Swedish nuclear energy vegetation: Ringhals, Forsmark, and Oskarshamn. Present purposes are restricted to parts not uncovered to excessive strain, although worldwide requirements for pressure-exposed components are in growth. “We hope that such a regular will likely be prepared within the close to future. As soon as it’s prepared, we will actually begin taking a look at putting in parts in our vegetation,” says Forssgren.

The know-how provides a number of benefits over conventional manufacturing strategies. These embrace minimal materials waste, sooner manufacturing instances, and the flexibility to digitally retailer designs relatively than bodily stock. A contemporary 3D printer with 4 laser sources can produce as much as 170 cubic centimeters of fabric hourly, making it an environment friendly manufacturing methodology.

Vattenfall, which owns 5 of Sweden’s six nuclear reactors, is exploring the opportunity of establishing an in-house 3D printing facility. Such a facility might doubtlessly provide components to different nuclear vegetation and energy era services throughout the firm. “The vegetation should not getting any youthful, and AM is a software for reaching our availability targets and decreasing the danger of manufacturing disruptions,” Forssgren explains.

Supply: group.vattenfall.com