Ursa Main, an aerospace and protection producer specializing in propulsion techniques, has expanded its additive manufacturing capability with the acquisition of three AMCM M 450-4 FLX techniques from EOS. The brand new machines convey Ursa Main’s fleet of EOS-powered gear to 6, all positioned at its rising manufacturing facility in Youngstown, Ohio. The growth is meant to speed up hypersonics and protection manufacturing for U.S. nationwide safety wants.

The funding displays Ursa Main’s resolution to align with EOS, an organization based in 1989 that develops industrial steel and polymer 3D printing platforms for world industries. “EOS and AMCM have been implausible to work with – confirmed reliability, a responsive U.S. service staff, and the most important deployed fleet of steel AM techniques within the nation,” stated Nick Doucette, Vice President of Operations at Ursa Main. He added that the collaboration is advancing new approaches to half and course of qualification, areas that stay central to broader adoption of additive manufacturing.

Ursa Main may even implement EOS’s laser toolpath API with direct engineering help, giving its staff extra freedom to customise builds for superior aerospace purposes. Greg Hayes, International Senior Vice President of Additive Minds at EOS, described the partnership for example of “the following period of additive manufacturing,” the place customers take higher management of course of improvement. Glynn Fletcher, President of EOS North America, emphasised Ursa Main’s technical capabilities, stating that the corporate illustrates how protection organizations can apply additive strategies to fulfill manufacturing calls for.

The AMCM M 450-4 FLX techniques function beam shaping know-how and be a part of an present fleet of 1 AMCM M 290-1 FLX and two EOS M 400 items. AMCM, a subsidiary of EOS, designs custom-made steel 3D printing techniques that may embody course of modifications corresponding to new laser configurations or tailored heating ideas. These machines are supposed to develop flexibility in supplies and geometries for propulsion parts. EOS continues to help this effort via its Additive Minds division, which gives engineering and course of experience to industrial customers.

Headquartered in Berthoud, Colorado, Ursa Main develops propulsion techniques for hypersonics, stable rocket motors, in-space propulsion, and orbital launch. The corporate’s applied sciences are designed for deployment throughout land, air, sea, and area, with the goal of revitalizing the U.S. protection industrial base. “Collectively, we’re difficult legacy approaches to half qualification and course of qualification, pushing all the additive trade ahead,” Doucette stated.

Scaling Manufacturing and Regional Progress

J.W. Speaker, a Wisconsin-based producer of lighting techniques for automotive and industrial sectors, just lately paired a Stratasys F3300 fused deposition modeling printer with PostProcess Applied sciences’ BASE help elimination system. The shift eradicated handbook bottlenecks corresponding to in a single day drying cycles, decreased turnaround occasions from one week to 9 hours in comparison with in-house machining, and delivered annual price financial savings of $60,000 to $75,000. The corporate now produces between 10 and 50 elements per week on a portfolio of six additive machines, with automation permitting bigger fixtures to be consolidated into single builds.

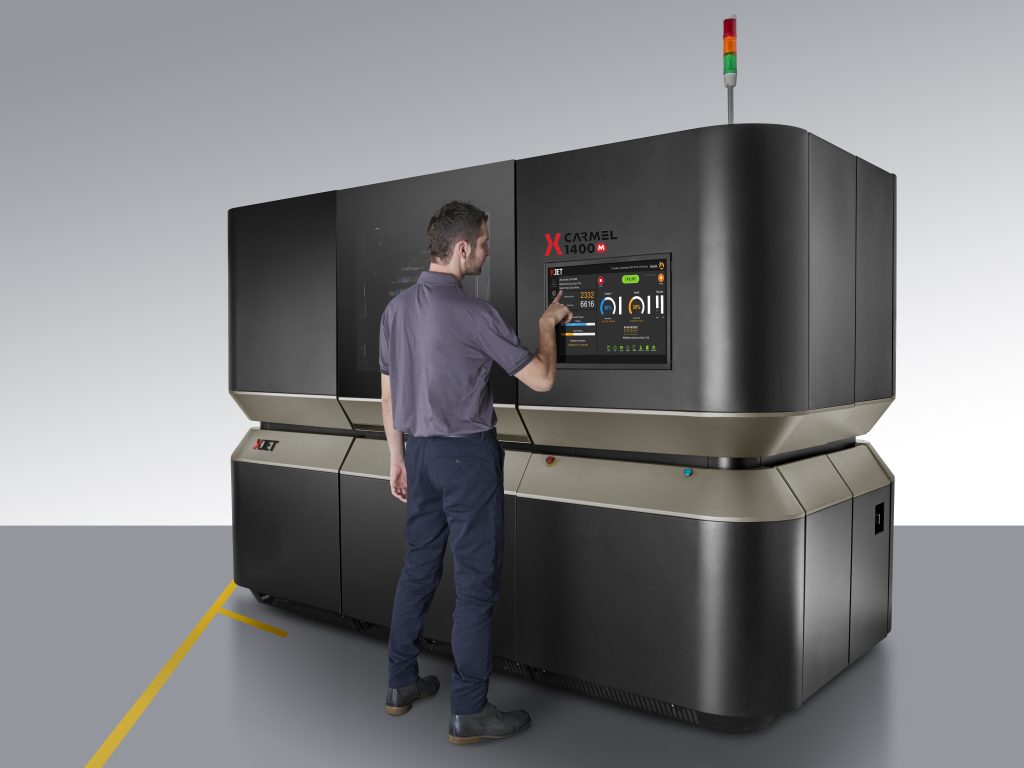

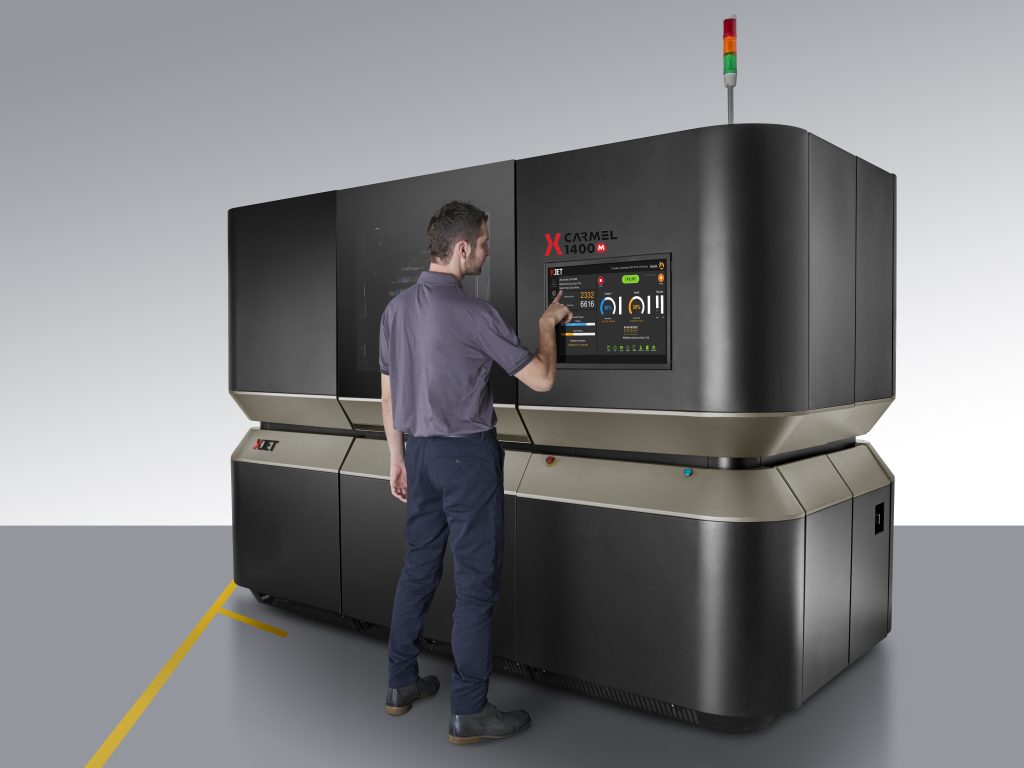

In Ohio, the Youngstown Enterprise Incubator (YBI) has expanded its steel and ceramic additive manufacturing capabilities by buying an XJet Carmel 1400M printer. Put in at Humtown Merchandise, a YBI companion and member of America Makes, the system employs NanoParticle Jetting know-how to ship ±50 micron accuracy on steel elements. The 1400M enhances YBI’s present XJet Carmel 1400C ceramic platform, put in in 2018, and can serve aerospace, protection, medical, and electronics prospects. Based on America Makes, the addition strengthens the Youngstown area’s place as a hub for high-precision additive manufacturing.

Restricted areas stay for AMA:Power 2025. Register now to hitch the dialog on the way forward for vitality and additive manufacturing.

Prepared to find who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication and comply with us on LinkedIn to remain up to date with the most recent information and insights.

Featured photograph exhibits Technicians at Ursa Main’s Youngstown facility function an EOS M 400 system. Picture by way of Ursa Main.